Sehlahisoa se setle ha se sebetsoe feela, empa hape se hloka liphekolo tse fapaneng tsa holim'a metsi ho fihlela ho hanyetsa kutu, ho hanyetsa ho roala, botle le ho eketsa bophelo ba ts'ebeletso.RCT MFG e na le boiphihlelo ba lilemo tse ngata ts'ebetsong ea CNC le ts'ebetso ea ho bopa ente, hape e fana ka letoto la lits'ebeletso ho tloha ho ts'ebetso ho ea ho kalafo ea holimo ho isa ho kopano.Ka hona, ho phaella ho thekenoloji ea maiketsetso, e boetse e na le phihlelo e ruileng ea phekolo ea holim'a metsi.Mekhoa e teng ea phekolo ea holim'a metsi e kenyelletsa: ho penta, pente ea ho baka, ho roala ha phofo, sandblasting, ho thunya ho thunngoa, anodizing, anodizing ea filimi e teteaneng, micro-arc anodizing, electroplating, electrophoresis, laser fatling, khatiso ea silika ea silika, tšepe e entsoeng ka brushed, ho bentša seipone, ho daea, blackening, CD pattern, etching, high gloss, etch pattern , Epoxy, joalo-joalo, thusa ho etsa lihlahisoa tsa hau boemong bo phahameng.

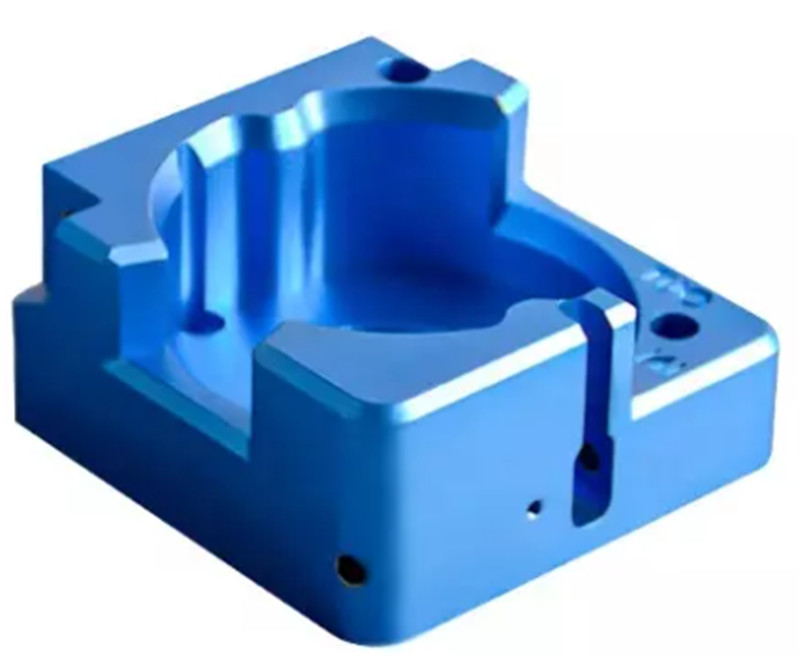

Anodizing

Ke mokhoa oa electrolytic oxidation, o fetolang bokaholimo ba thepa hore e be filimi e sireletsang, e etsang hore ho be thata ho oxidize le ho senya, ho lelefatsa bophelo le ho finyella ponahalo ea mebala e sa tšoaneng.Mekhoa e tloaelehileng ea phekolo ea anodizing e arotsoe ka: anodizing e tloaelehileng , anodizing ea tšepe e entsoeng ka brushed, anodizing e thata, anodizing e teteaneng ea filimi, micro-arc oxidation, joalo-joalo Thepa e ka bang oxidized ke: aluminium alloy, magnesium alloy, titanium alloy, joalo-joalo.

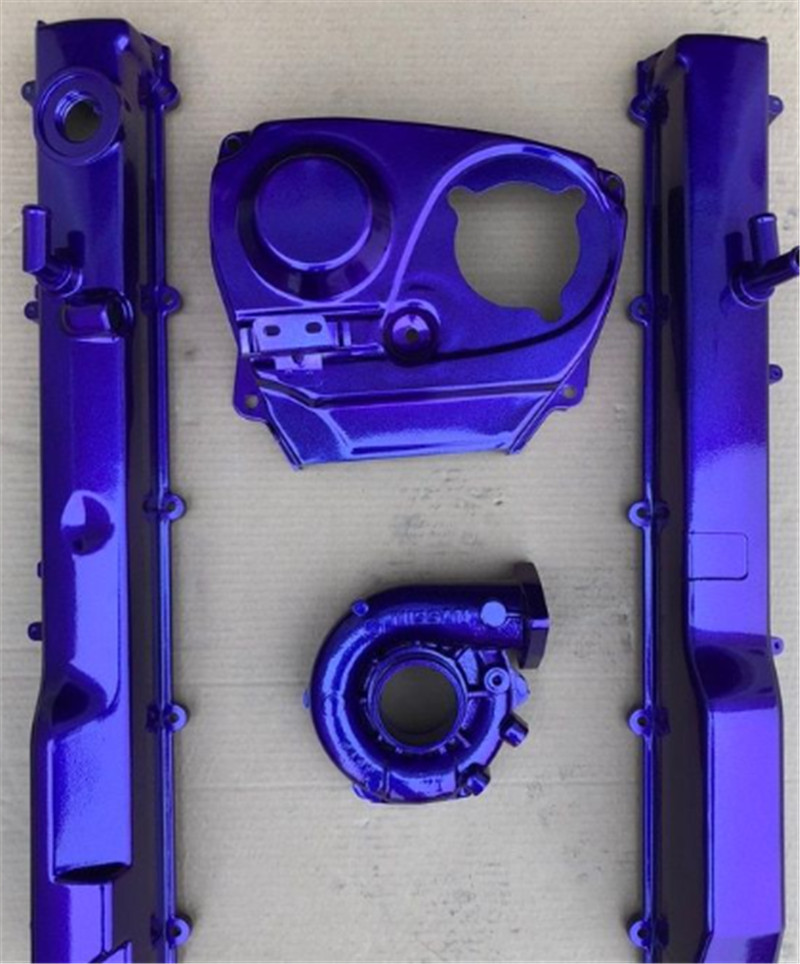

Electroplating

Mokhoa oa motheo oa electroplating ke ho qoelisa karolo ka tharollo ea letsoai la tšepe e le cathode, le poleiti ea tšepe e le anode, le ho fetisa hona joale ho kenya seaparo se lakatsehang karolong eo.Phello e nepahetseng ea electroplating e tla etsa hore sehlahisoa sa hau se be fesheneng se phahameng le ka sona.Ho ea 'marakeng o betere, electroplating e tloaelehileng e kenyelletsa plating ea koporo, nickel plating, plating ea silevera, plating ea khauta, chrome plating, galvanizing, tin plating, vacuum plating, joalo-joalo.

Ho roala ka electrophoretic

Ka ntlafatso e tsoelang pele ea tlhokahalo ea indasteri, theknoloji ea ho roala ha Electrophoretic e ka etsa mebala e fapaneng, ea boloka ho benya ha tšepe le ho ntlafatsa ho hanyetsa ha kutu ea bokaholimo, e nang le tšusumetso e nyane ho nepahala ha sehlahisoa.Botenya bo ka ba 10-25um, 'me tse teteaneng le tsona li ka etsoa

Boikemisetso

Passivation, eo hape e tsejoang e le kalafo ea chromate, ke mokhoa oa ho khetha o tlosang mafura a holim'a metsi, mafome le li-oxide ka ho qoelisoa kapa ho hloekisa ka ultrasonic.Ka karabelo ea lik'hemik'hale ea tharollo ea passivation, e ka thibela kutu le ho lelefatsa mafome.'Mala oa filimi ea passivation e tla fetoha ka lisebelisoa tse fapaneng.Passivation e ke ke ea eketsa botenya ba sehlahisoa, 'me ha ho hlokahale hore u tšoenyehe ka eona e amang ho nepahala ha sehlahisoa.

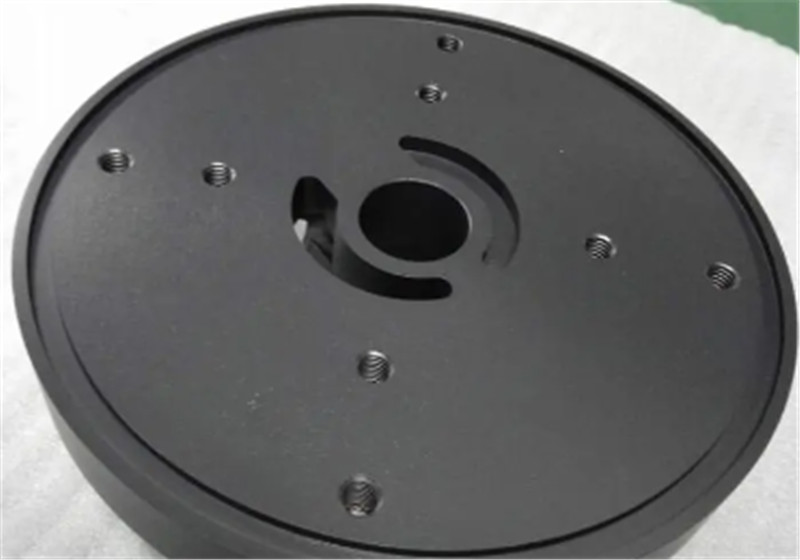

E ntshofetse

Ho fifala ho boetse ho bitsoa bluing.Molao-motheo ke ho qoelisa sehlahisoa ka tharollo e matla ea lik'hemik'hale ea oxidizing ho etsa filimi ea oxide holim'a tšepe ea tšepe ho arola moea le ho finyella morero oa ho thibela mafome.Mokhoa ona o sebetsa ho thepa ea tšepe.

QPQ (Quench-Polish-Quench)

E bolela ho kenya likarolo tsa tšepe tse nang le tšepe ka mefuta e 'meli ea libate tsa letsoai tse nang le thepa e sa tšoaneng, le ho kenya likarolo tse sa tšoaneng ka holim'a tšepe ho etsa lera le kopanyang le kenang, e le ho finyella morero oa ho fetola bokaholimo ba likarolo.E na le khanyetso e ntle ea ho apara, ho hanyetsa mokhathala, ho hanyetsa kutu le ho senyeha ho honyenyane.Ts'ebetso ena e sebetsa ho lisebelisoa tsohle tsa tšepe.

(Tlhokomeliso: Lihlahisoa tsa tšepe tse sa hloekang li ke ke tsa ntšoa, 'me bokaholimo bo ka ntšoa feela ke QPQ)

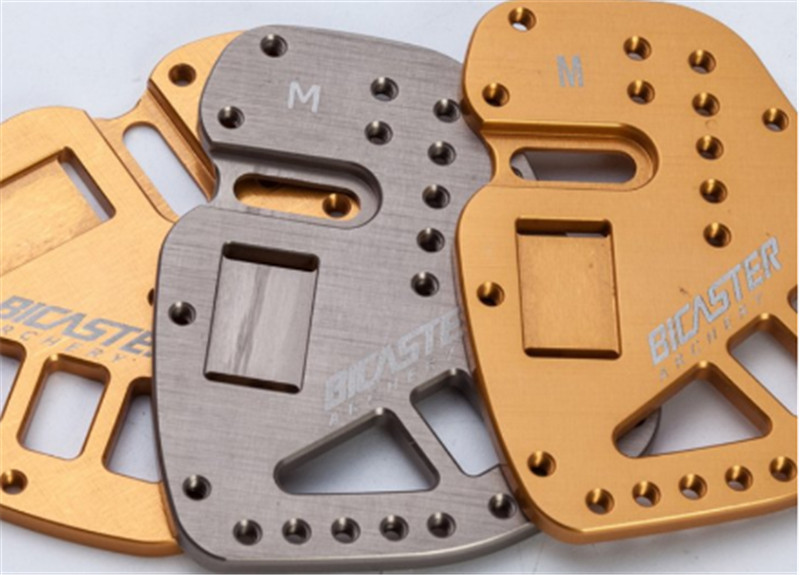

Ho betla ka laser

Laser engraving, eo hape e bitsoang laser marking, ke ts'ebetso ea kalafo e holimo e sebelisang melao-motheo ea optical ho theha LOGO kapa lipaterone lihlahisoa.Laser engraving effect ke ea ka ho sa feleng, boleng ba bokaholimo bo holimo, 'me e loketse lihlahisoa tse entsoeng ka lisebelisoa tse fapaneng tsa tšepe le tsa polasetiki.

Khatiso ea skrine ea silika

Khatiso ea skrine ea silika e bolela hore enke e fetisetsa mohlala ho sehlahisoa ka skrine.'Mala oa enke o ka etsoa ho latela litlhoko tsa bareki.RCT MFG e entse mebala ea 6 sehlahisoa se le seng, ho kenyeletsoa botšo, bofubelu, boputsoa, bosehla le bosoeu.,tala.Haeba u batla hore phello ea khatiso ea skrine ea silika e be e tšoarellang haholoanyane, u ka boela ua eketsa lera la UV ka mor'a khatiso ea skrine ea silika ho lelefatsa bophelo ba eona.Khatiso ea skrine ea silika e loketse lisebelisoa tse fapaneng tsa tšepe le polasetiki, hape e ka kopanngoa le phekolo ea holim'a metsi e kang oxidation, penta, phofo ea ho fafatsa, electroplating le electrophoresis.

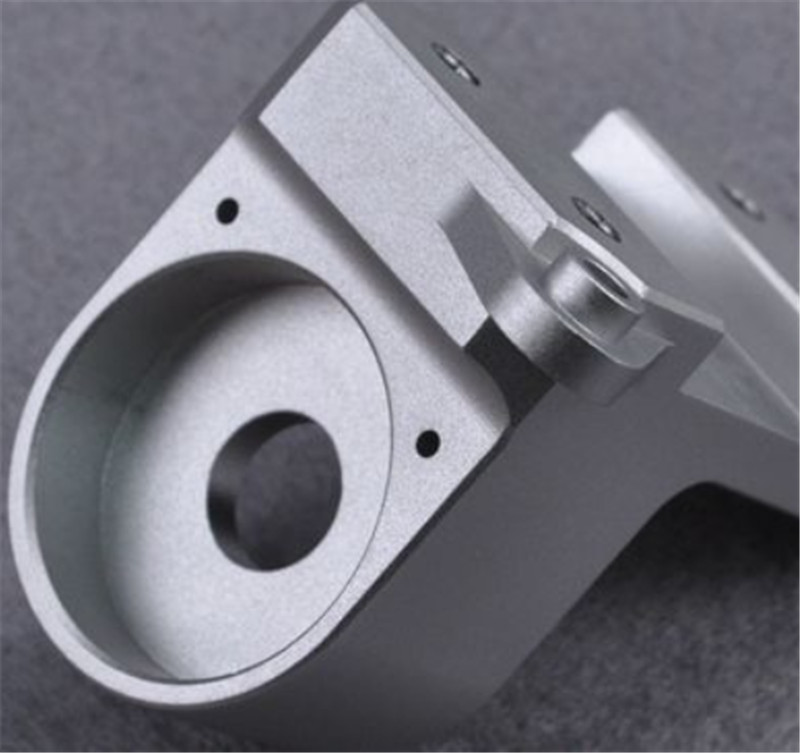

Ho benya

Ho benya ke ho etsa hore sehlahisoa se be setle, se fetele le ho sireletsa bokaholimo.Ho benya le ho pepeseha ke khetho e ntle ho uena.Ho belisoa ha lihlahisoa tsa hardware ho arotsoe ka ho bentša ka letsoho, ho bentša ka mechine, le ho belisoa ka electrolytic.Electrolytic polishing e ka sebelisoa ho nka sebaka sa ho belisoa ha mochini o boima, haholo-holo bakeng sa likarolo tse nang le libopeho tse rarahaneng le likarolo tseo ho leng thata ho li sebetsana ka mokhoa oa ho belisa ka letsoho le mekhoa ea mechine.Electrolytic polishing hangata e sebelisoa bakeng sa tšepe, aluminium, koporo le likarolo tse ling.

Brushed Metal

Brushed metal ke mokhoa oa ho phekola ka holim'a metsi o etsang mela ka holim'a sebaka sa mosebetsi ka lebanta la abrasive le petelitsoeng ka sephara le borashe ba rolara e sa lohiloeng ho fihlela phello ea mokhabiso.Kalafo ea holim'a brushed e ka bonahatsa sebopeho sa lisebelisoa tsa tšepe, 'me e ntse e tsebahala haholoanyane bophelong ba kajeno.E sebelisoa haholo lifonong tsa cellular, likhomphutha, limonita, thepa ea ka tlung, lisebelisoa tsa motlakase le likhetla tse ling.

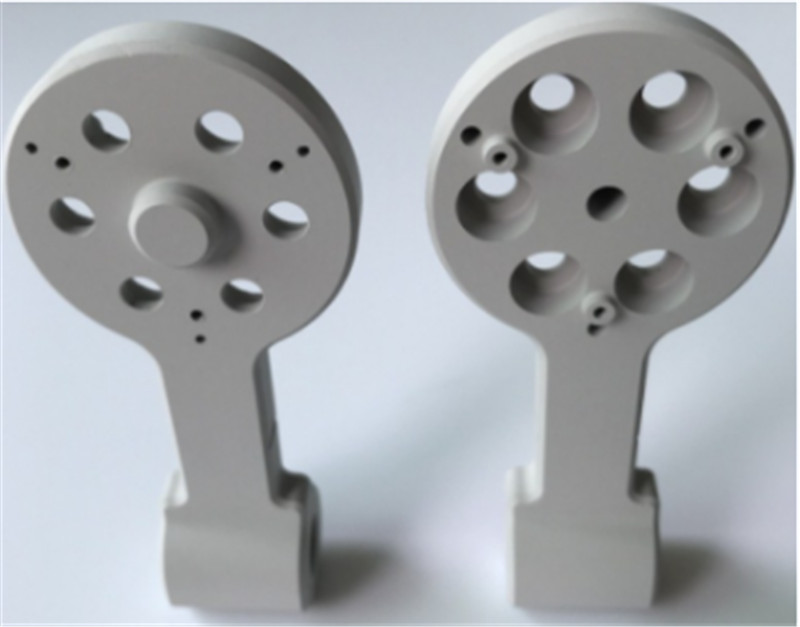

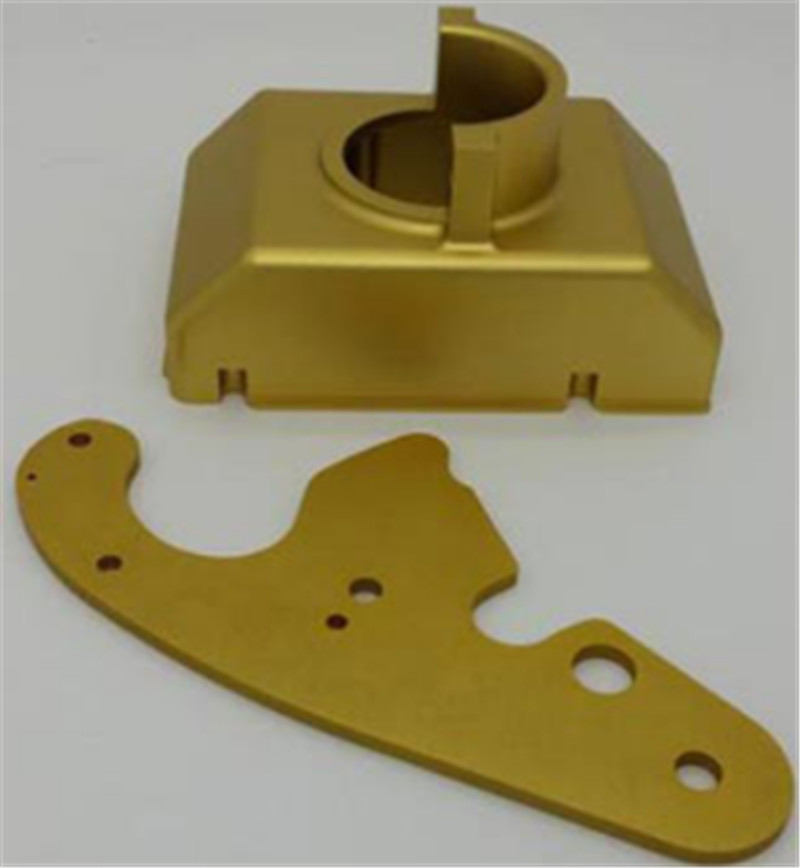

Ho fafatsa ka pente le ho fafatsa phofo

Ho fafatsa ka pente le ho fafatsa ka phofo ke mekhoa e 'meli e tloaelehileng ea ho phekola ka holim'a likarolo tsa hardware, 'me ke mekhoa e sebelisoang ka ho fetisisa ea holim'a metsi bakeng sa likarolo tse nepahetseng le ho etsa li-batch tse nyenyane.Li ka sireletsa bokaholimo ho kutu, mafome, hape li ka fihlela phello e ntle.Ka bobeli ho fafatsa phofo le ho penta ho ka etsoa ka mokhoa o fapaneng (mela e metle, mela e thata, mela ea letlalo, joalo-joalo), mebala e fapaneng, le maemo a fapaneng a khanya (matte, flat, high-gloss).

Ho qhomisa lehlabathe

Sandblasting ke e 'ngoe ea liphekolo tse sebelisoang hangata holim'a lihlahisoa tsa Hardware.E ka ntlafatsa bohloeki le bohloeki, 'me ea eketsa ho khomarela le ho tšoarella pakeng tsa sehlahisoa le ho roala.Ka hona, mekhoa e mengata ea phekolo ea holim'a metsi e khetha sandblasting e le phekolo ea bona ea pele.Tse kang: sandblasting + oxidation, sandblasting + electroplating, sandblasting + electrophoresis, sandblasting + dusting, sandblasting + pente, sandblasting + passivation, joalo-joalo.

Ho fafatsa ka Teflon

E boetse e bitsoa ho fafatsa Teflon, ke phekolo e ikhethang haholo ea holim'a metsi.E na le litšobotsi tse phahameng tsa anti viscosity, non viscosity, khanyetso e phahameng ea mocheso, khohlano e tlase, boima bo phahameng, ho se kolote, le khanyetso e phahameng ea lik'hemik'hale.Ka hona, e sebelisoa haholo indastering ea lijo, li-tableware, kitchenware, indasteri ea pampiri, lisebelisoa tsa bongaka, lihlahisoa tsa elektroniki le lihlahisoa tsa koloi, lisebelisoa tsa lik'hemik'hale, joalo-joalo, 'me li ka sireletsa thepa ho tloha ho bola ha lik'hemik'hale ho lelefatsa bophelo ba tšebeletso ea lihlahisoa.

Etching

Etching ke mokhoa oa ho tlosa lintho ka ho sebelisa karabelo ea lik'hemik'hale kapa tšusumetso ea 'mele.Hangata e bua ka etching, eo hape e tsejoang e le photochemical etching, e bolelang ho tlosa filimi e sireletsang ea sebaka seo se lokelang ho kenngoa ka mor'a ho etsoa le ho nts'etsopele ha poleiti ea ho pepeseha, le ho kopana le tharollo ea lik'hemik'hale nakong ea etching ho finyella phello ea ho qhibiliha le ho bola, ho etsa phello ea sekoahelo se bopehileng kapa se bopehileng.

IMD

Mokhabiso oa Mold (IMD) ke mokhoa o theko e boima oa ho khabisa likarolo tsa polasetiki.E na le mehato e mene: Ho Hatisa, Ho Theha, Ho Poma le Ho Bopa ka Ente.'Me Ke theknoloji e tummeng ea machaba ea ho khabisa holim'a metsi.Bokaholimo bo thata ebile bo bonaletsa filimi, lera la paterone ea khatiso e bohareng, lera le ka morao la ente, 'me bohareng ba enke ho ka etsa hore sehlahisoa se se ke sa khohlano., ho thibela bokaholimo hore bo se ke ba ngolisoa, ’me bo ka boloka ’mala o khanya ’me ho se bonolo ho nyamela ka nako e telele.

Pad Printing

Pad printing, eo hape e bitsoang tampography kapa tampo printing, ke mokhoa oa khatiso o sa tobang oa offset (gravure) moo silicon pad e nkang setšoantšo sa 2-D ho tloha poleiting ea khatiso ea laser e ngotsoeng (e boetse e bitsoa cliché) ebe e e fetisetsa ho 3- D ntho.Ka lebaka la khatiso ea pad, hona joale ho khoneha ho hatisa mefuta eohle ea lihlahisoa tse thata tse bōpehileng joaloka curved (convex), hollow (concave), cylindrical, spherical, angle angles, textures, joalo-joalo tse neng li sa fumanehe ka mekhoa ea khale ea khatiso.

Khatiso ea ho fetisa metsi

Khatiso ea ho fetisa metsi ke mofuta oa khatiso o sebelisang khatello ea metsi ho hydrolyze pampiri ea ho fetisa / filimi ea polasetiki e nang le mebala ea mebala.Ts'ebetso ea thekenoloji e kenyelletsa tlhahiso ea pampiri ea khatiso ea phetisetso ea metsi, ho inela pampiri ea lipalesa, ho fetisa mohlala, ho omisa le sehlahisoa se felileng.

Ho roala ka conductive

Conductive coating ke mofuta oa pente e ka sebelisoang ho fafatsa.E ka tsamaisa motlakase ka mor'a ho omisa ho etsa filimi ea pente, e le ho sireletsa tšitiso ea motlakase.Hajoale, e sebelisoa libakeng tse ngata tsa sesole le tsa lehae tse kang lisebelisoa tsa elektroniki, lisebelisoa tsa motlakase, lifofane, indasteri ea lik'hemik'hale, khatiso, jj.

Nako ea poso: Apr-11-2023