CNC Mechine ea housigg ea tšepe e sa hloekang bakeng sa Indasteri ea Lisebelisoa tsa Khatello ea Khase

Melemo ea likarolo tsa Precision CNC Machining ke life?

Mokhoa o phahameng oa ho sebetsa oa CNC o loketse mesebetsi e le 'ngoe le tlhahiso ea molumo o tlase ho isa ho o phahameng (ho tloha ho likarolo tse 500 ho isa ho tse 10,000 ka beke), ka lebaka la ho pheta-pheta ho phahameng.

Melemo ea mantlha e amanang le mamello e haufi ea tlhahiso ea mochini oa CNC, e kenyelletsa:

●Ho pheta-pheta holimo

●E fihlella mamello e thata haholo

●Lisebelisoa li fana ka thepa e ntle haholo le e felletseng ea isotropic

●E loketse lits'ebetso tse ngata tsa boenjiniere

●E theko e boima bakeng sa geometry e rarahaneng

●Lebelo le babatsehang ho nts'etsopele ea 'maraka

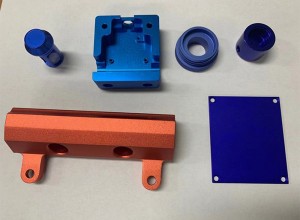

●Litlhaloso tsa CNC Machining ea housigg ea tšepe e sa hloekang bakeng sa Indasteri ea Lisebelisoa tsa Khatello ea Khase

| Lintho tse bonahalang | tšepe e sa hloekang304, SS316, tšepe | ||||||||

| Max.boholo ba mochini | 510 * 1020 * 500 limilimithara(boholo) | ||||||||

| Mamello | ho latela tlhoko ea ho taka ea 2D, ka tloaelo +/-0.05mm | ||||||||

| Kalafo ea Bokaholimo | Anodized (Mofuta oa II Kapa Mofuta oa III), chrome plating, silevera plating, polishing, galvanized, electroplating, passivation, ho roala phofo, ho fafatsa le ho penta, joalo-joalo. | ||||||||

| Mokhoa o ka Sehloohong | CNC machining, turning, lathing, milling, cheka, grinding, boring, stamping, threading, tamping, EDM, terata tsamaea, laser cutting, laser tšoaea, le holim'a kalafo | ||||||||

| Taolo ea Boleng | Taolo ea Boleng bo tiileng ts'ebetsong eohle, ho tloha ho thepa ho isa ho ho paka | ||||||||

| Indasteri CT scanning, projeke ea 3D, theknoloji ea X-ray, mochini o lekanyang oa Coordinate | |||||||||

| Tšebeliso | Indasteri ea Lisebelisoa tsa Khatello ea Khase | ||||||||

| Bolumo | 10-10,000 Lota boholo | ||||||||

| Metako e Ikemetseng | Auto CAD, JPEG, PDF, STP, IGS, le liforomo tse ling tse ngata lia amoheloa | ||||||||

Re fana ka lits'ebeletso tsa machining tsa CNC tse emisang hang le ka potlako, ho kenyeletsoa ho fetola ka nepo CNC, ho sila ka CNC, le ts'ebeletso ea ho sila ea CNC.Hape le lits'ebetso tse ling tsa bobeli tsa machining, joalo ka ho cheka, ho penya, ho bora, ho roala, ho kokota, joalo-joalo. Re na le bokhoni ba ho etsa likarolo tsa mochini oa CNC tse nang le lisebelisoa tsa boleng bo holimo ka theko ea tlholisano, kapa ho fana ka likeletso tsa tlhahiso ho etsa tloaelo ea hau ea CNC. likarolo ho bonolo ho hlahisa le ho boloka chelete e ngata.Ikopanye le rona hona joale bakeng sa projeke ea hau ea likarolo tsa mochini oa CNC.

Mechini ea ho etsa hlobo